A complete set of laser processing application solutions provider

A complete set of laser processing application solutions provider

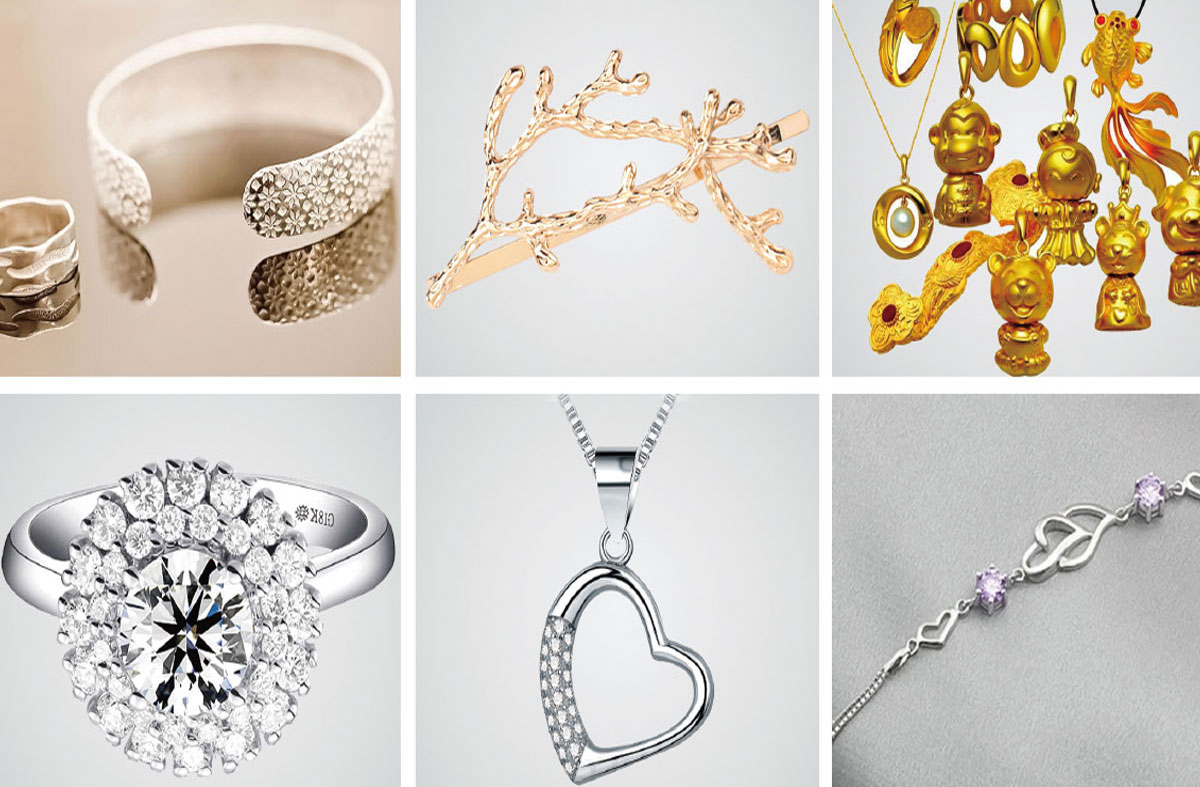

In the jewelry decoration industry, the traditional processing technology has high cost, long cycle and poor customer experience. Laser processing technology has a significant advantage. In recent years, laser processing technology has become more and more widely used in the ornament industry, including laser welding, laser rapid prototyping, laser marking, laser engraving and laser cutting.

Laser welding has a remarkable advantage over traditional welding technology: the introduction of rapid prototyping technology greatly shortens the time from the ornament pattern to the original version; the use of laser marking and laser engraving enriches the means of the ornament surface treatment, which can further satisfy the demand of individual jewelry, and the laser cutting can achieve small loss. Laser processing technology is playing an increasingly important role in the jewelry industry.

Laser surface alignment technology is an early laser processing technology. It uses evaporation and ablative material to produce the required marks. Compared with traditional jewelry marking technology, the main advantages are as follows: 1. using computer control, more easy to change graphics; 2. using laser processing to depict fine, adapt to modern production high efficiency, fast rhythm requirements; 3. material applicability, good durability, without external force can guarantee the precision of jewelry; 4. processing mode flexible and suitable Combined with any batch production; 5. environmental protection and no pollution.

Laser welding has the characteristics of high welding strength and speed and low reject rate. It is widely used in jewelry manufacturing. Compared with the traditional welding technology, it has the following advantages: 1. fast speed, high strength, small deformation, no orthopedics and cleaning after welding; 2. suitable for welding precision workpiece to ensure processing quality; 3. high precision assembly, help to develop new technology; 4. consistency and stability; 5. simplification of workpiece repair work; 6. environmental protection without pollution. Dye; 7. save processing metal material.

Laser engraving works in a continuous or repetitive way. It assists in protecting gas from oxidation during work. Laser engraving can be regarded as a linear extension of laser marking technology. Under appropriate focusing, some laser points with a diameter of 30um can engrave a very small pattern, and engraving in the area of the square of 1mm is not only beautiful but also a anti-counterfeiting function.

Laser rapid prototyping is a new technology developed on the basis of the comprehensive application of various modern technologies (such as computer aided design, computer aided manufacturing, computer digital control, laser technology and new materials etc.). Computer design can be quickly transformed into solid models, in short, attributable to 3D printing. This technology is mainly used in jewelry manufacturing, such as the forming of the original mold, the lost foam and wax mold manufacturing. Laser rapid prototyping technology can greatly shorten the product development cycle.