A complete set of laser processing application solutions provider

A complete set of laser processing application solutions provider

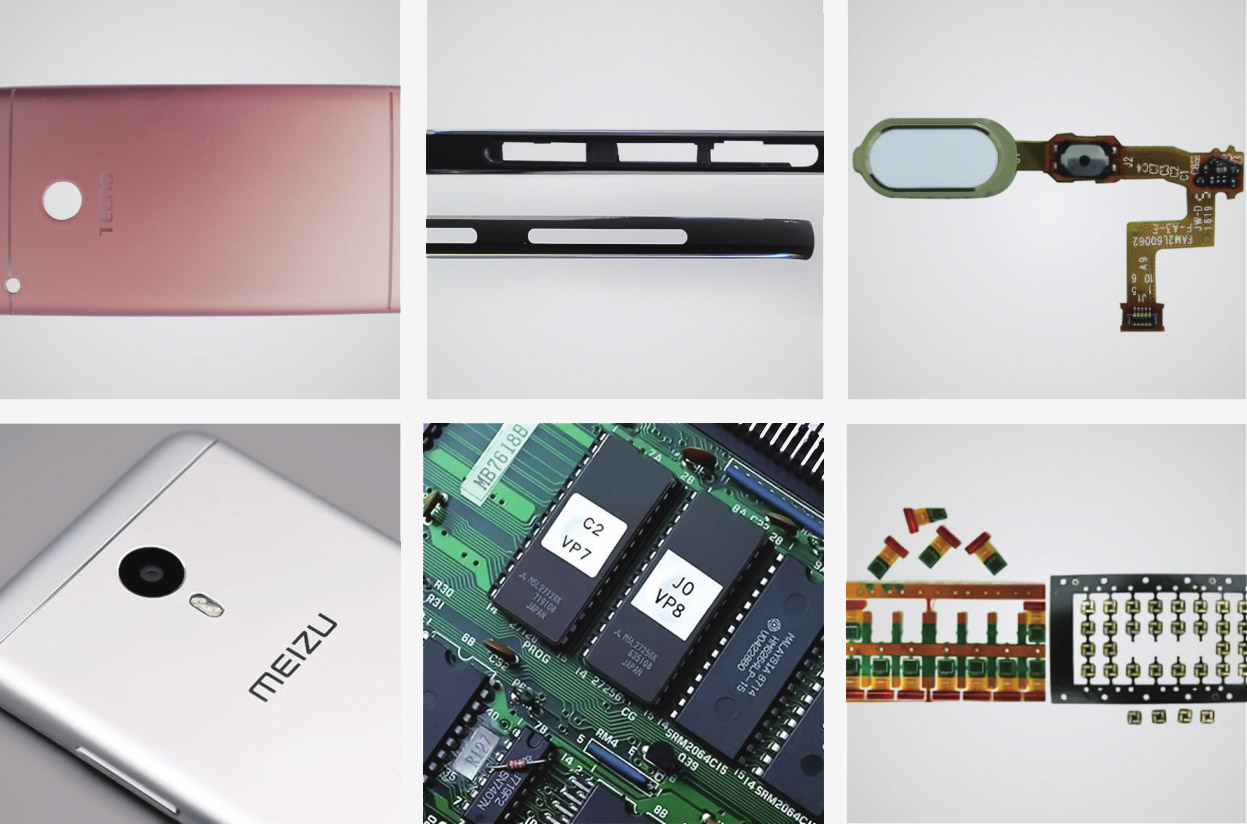

In the mobilephone communications industry, the mobile phone is a necessary communication tool for people in the information age, and in the process of use, we can find the shadow of the laser marking everywhere. Logo marking, mobile phone key marking, mobile phone shell marking, cell phone battery marking, mobile phone jewelry marking and so on, even in the inside of the mobile phone you can't see, and the laser marking of parts. Therefore, unconsciously, laser marking has entered our life and brought about changes in beauty in our lives.

Laser engraving is based on extremely subtle spots, symbols, words, patterns, and so on. The size of the spot can be in the order of microns. It has a deeper meaning for microprocessors and security.

After focusing, the fine laser is like a sharp blade, which can remove the material from the surface of the object by point. The advantage is that the marking process is non-contact processing, does not produce negative scratches and friction, and will not cause extrusion or crush injury. So it will not damage the items to be processed. As the laser beam becomes focal again, the spot becomes finer. The thermal effect area is small and the machining accuracy is very high. Therefore, it can accomplish some industrial arts which cannot be completed by conventional methods and can not be realized.

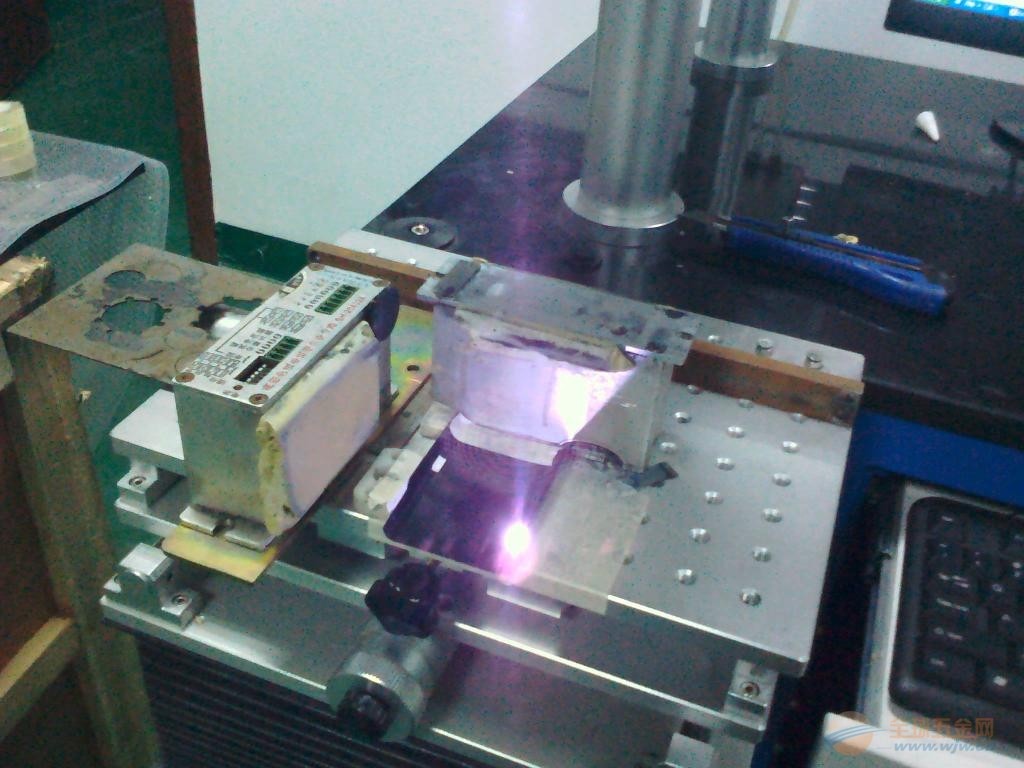

Laser cutting has become the development direction of modern metal processing technology because of its high speed, high precision, high quality, energy saving and environmental protection. In laser processing applications, laser cutting accounts for 32% of the market share. Compared with other cutting methods, laser cutting is characterized by high speed, high accuracy and high adaptability. At the same time, it has the advantages of small seams, small heat affected zone, good cutting surface quality, no noise in cutting, good verticality edge of cutting edge, smooth cutting edge, easy to realize automatic control and so on. When laser cutting plate, no mold is needed. It can replace some punching and cutting methods which need complex large mold. It can greatly shorten the production cycle and reduce the cost.

Sheet metal processing is the key technology that sheet metal technicians need to master, and is also an important process of sheet metal forming. It not only includes traditional cutting and blanking, blanking and bending forming and other methods and processes, but also includes various cold stamping die structure and process parameters, the working principle and operation method of various equipment, and also includes new stamping technology and new technology. The sheet metal processing parts of agricultural machinery products generally adopt 4-6mm steel plate, many kinds of sheet metal parts, and update quickly. The traditional sheet metal parts of agricultural machinery products usually use punching machine way, and the die loss is big. Usually a large agricultural machinery manufacturer is used for the storage of the mould for the warehouse of nearly 300 flat meters, so it can be seen that the parts are processed if they are processed. Remain in the traditional way, will seriously restrict the rapid upgrading of products and technology development, and laser flexible processing advantages are reflected.